5 - Irrigation

Irrigation for golf course maintenance is an important part of the golf course operation. It’s crucial to maintain irrigation practices that support conservation and operating standards.

Before an owner or company begins construction, a water source must be obtained. A system is needed when rainfall is not enough to sustain healthy playable turf, especially during dry periods. In the event a new well is to be constructed, owners will need a well driller with a Hawai’i C-57 license. All work requiring the installation of pumps and pumping equipment will require either a well drillers with a Hawai’i C-57, pump installers with a license C-57a license (pumps installation contractor), or a general contractor with an A (general engineering) license. Guidelines and requirements for well construction, pump installation and well abandonment is can be found in the Hawai’i Well Construction and Pump Installation Standards (February 2004).

The Department of Land and Natural Resources, Commission on Water Resource Management (CWRM) will work with the contractor on required permits. CWRM regulates all ground water and surface water use. All appropriate Permits for well construction, pump installation and well abandonment need to be submitted to CWRM for approval (HAR 13-168-12). In event that the Well is located within a Water Management Area, a Water Use Permit will also need to be obtained, only wells for domestic consumption are exempted from this requirement. If there is an existing well, these contractors are licensed (as indicated above) to investigate and facilitate maintenance.

Once permitting is achieved and the well is installed, it is the owner’s responsibility to understand what will need to be reported to the state or county. A Monthly Ground Water Use Report, which includes Quantity Pumped, Salinity (Chloride and/or Conductivity) with temperature, and Water Level, is required (HAR 13-168-7) to be submitted to CWRM. All guidelines from the state water commission must be followed.

WATER SOURCES

Many sources of water can be used for irrigation. Water sources should be investigated on supply and quality for selected turf. Sources include potable water, well water, reclaimed water, desalinized water, and blends of multiple sources.

Potable water: Water suitable for drinking. Used where no other alternatives for securing water are possible. Often the most expensive water source. Sustains many Hawai’i turf selections for golf courses.

Well water: Underground water held in the soil and in pervious rocks. Used from an aquifer of water floating on saltier water. Requires a motor, pump, and state permits. Quality can range from fresh, brackish to salt water. Analyzing for Chloride or measuring the conductivity can determine the quality. Depending on salinity, this water could influence turf selection.

Surface water: Water from streams, ditches or diversions. Requires a state permit from CWRM.

Reclaimed water: Water processed from converting wastewater to a form reused for other purposes such as irrigation. It is common in Hawai’i to use water from large treatment plants. A contract is negotiated with the Water Company. Special attention should be noted on cost, amount, timing, and length of contract before renewal. Quality can range from good to bad. Testing is needed to analyze quality. Depending on salinity, this water could influence turf selection.

Desalinization: A process of removing salt and other minerals from ocean water to make it suitable for agricultural use or human consumption. Most common methods use reverse osmosis and force water through membranes that collect salt and other molecules from passing. Correct disposal of the brine generated in the process is necessary. Generally a more costly alternative.

EQUIPMENT & CONTROLS

Irrigation Design

An irrigation designer and water quality specialist should be hired to evaluate the site, water quality mitigation requirements, and water availability. An owner should make the designer aware of details such as plant materials, soils, elevation, expectations, and budget. Based on pre-planning meetings the designer will be able to produce drawings for the pump station, hydraulics, configure pipe sizing, and decide sprinkler locations. The water quality specialist will assist in determining any required source balancing delivery system (blending needed to allow for a waters acceptability), material requirements (types of metals best suited for components used in the delivery system), flushing requirements, as well as future complications that could arise from water quality issues.

Pump Station

Kohanaiki Pump Station

The pump station needs to be sized correctly to deliver the most efficient use of water and electricity. The pump station should consist of Variable Frequency Drive (VFD) motors, pressure sensors (both high and low), water meters, and leak detection.

VFD motors: Regulate water pressure and deliver pump control based on pressure. Reduce energy costs by alternating pump starts and running at lower RPMs based on flow and pressure needed for the system.

Pressure Sensors: Provide adjustable sensor pressure to maintain optimal system pressure with current flow; can set high and low pressure levels for automatic shutdown.

Water Meters: Current flow monitored by control unit to optimize energy consumption.

Leak Detection: A combination of pressure and water output that can activate shutdown for low pressure.

Gravity Feed

Some courses use gravity to supply pressure to the irrigation system. This type of system uses Pressure Reducing Valves (PRV) to regulate pressure as it travels downhill. This design has the reservoir placed at a higher elevation than the highest point of area needing water. The system uses less energy to run, as electrical motors are not needed to supply pressure. There is maintenance required with quarterly upkeep to the PRVs, but compared to energy costs, it is much less.

Central Computer

The central computer is the brain of irrigation. By creating programs and schedules, superintendents are able to optimize water management and maximize course playability. Managers can allow for time adjustments, use weather stations for a baseline, and help control costs by using efficiency to run the shortest water cycle with the best pressure and distribution.

Programs are areas within the central computer that let you define areas on the golf course. It is common for courses to have 12 to 40 programs. For example, a course may have a program called “greens”, another called “tees”, and another designated as “fairways”. These programs can allow superintendents to irrigate designated areas for a defined period of time. Within each program there are individual heads connected to its program, or area. Each of these heads can be adjusted based on the environment around it. So a sprinkler could water 50 percent, 80 percent, 100 percent, 120 percent, 130 percent, etc. The higher the percentage, the more water delivered. Schedules are days in which each program will water. A course manager may use soil moisture readings or visual inspection to decide what programs will run on a scheduled day.

Weather stations are also part of the central computer system. A weather station can record environmental variables across the course. The station is able to record sun intensity, temperature, humidity, wind, and rain. It uses data collected to produce a daily reading called evapotranspiration (ET). ET is the process by which water is transferred from the land to the atmosphere by evaporation from the soil and other surfaces and by the transpiration of plant cells.

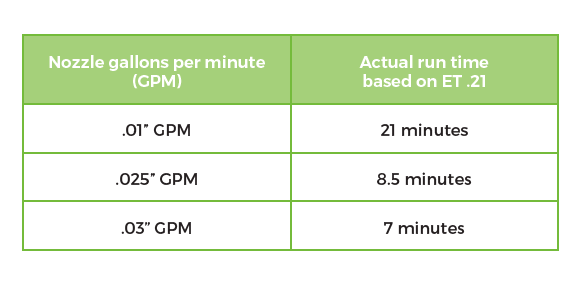

Many managers use the weather station to calculate ET to determine amount of water that needs to be returned to the soil. Below is a basic visualization and calculation of converting ET to a run time based on nozzle size of the sprinkler.

WATER MANAGEMENT

Having a superior designed system has allowed superintendents to control water not only by area, but down to specific sprinkler heads on the course. Managers are using other tools and technology as well to conserve water. Tools include the weather station to monitor ET, soil moisture meters, infrared pictures to detect hot spots quicker, hoses, and live feeds of the system via a computer or smart phone.

Hand watering collars on green

Reduction of manicured turf can help cut down water consumption. Maintained areas that are out of play can be converted to a native species that requires only local rainfall to survive.

Another area to gain water conservation is by separating the landscape into a separate program. Clubhouse and common areas, with correct species selection, can require one to two cycles of irrigation per week compared to four or five cycles for turf. You can also use drip irrigation in landscape areas to supply water only to the plants that need it. Utilize reclaimed water when possible. Separate irrigation zones within landscapes, combine plants with similar water requirements (verses watering to the highest water requiring species in a planting) to minimize water usage and pruning requirements.

Sensors that are placed in the soil, or portable sensors operated by hand, can be used to monitor soil moisture. Through record-keeping and visually inspecting, a manager can make a water decision based on percentage of moisture in the soil. Each course will need to set an acceptable threshold. Once the threshold falls below the acceptable level, then the area can be watered by hand or with the overhead sprinkler.

Digital reading of volumetric water content percentage and average moisture of green

MAINTENANCE

Irrigation systems require maintenance to continuously run efficiently. Preventive maintenance can be handled by the course or by outside companies. Managers and irrigation technicians perform daily inspections of the system in the field. These include visual inspections for leaks in pipes or heads, stuck-on heads, monitoring actual flow to projected flow, meter readings, and computer logs. More detailed inspections are done with less frequency, but are just as important.

Weekly inspections are more detailed. These include inspecting individual clocks, running the system and watching sprinklers, cleaning filters at the pump station to remove debris, checking rotation of heads, and adjustments. This can be done while watering-in products or by checking areas that are too wet or too dry.

Quarterly inspections may or may not be done internally. Testing consists of reading electrical current drawn by pumps, voltage at breakers, recording run time hours, inspecting motors, cleaning PRV, and cleaning of the clay valve. This inspection should be recorded and kept onsite to help avoid significant maintenance issues.

Every manager should check all sprinklers on the course annually. Each sprinkler should be thoroughly inspected and worn parts need to be replaced. Nozzle wear may not be visible to the eye, however can impact distribution of water, operating pressure, water consumption, and rotation. Each head should be recorded so the central computer can match the field audit. A visual inspection of the reservoir should be included.

TYPES OF IRRIGATION

Delivery of water to the turf can be achieved in numerous ways. Irrigations systems can consist of different types of sprinklers to conserve water and provide even distribution. Irrigation heads on golf courses can be full circle or part circle and deliver large amounts of water to areas such as greens, tees, fairways, and roughs. These sprinklers can have coverages of 20 to 80 feet and are operated one to two at a time from a central controller. In scenarios where areas aren’t as big in size, a smaller rotor or pop up head can be used to conserve water, distributing only to the turf needing irrigation. These heads can cover 5 to 20 feet and are operated in a series of heads off of one valve.

In other circumstances, drip irrigation may be needed. This is a tube laid in the ground or above ground that delivers small amounts of water to plant material. It is most notably used in landscaping. Quick couplers should be throughout the golf course and used when small areas need additional water. Typically, it is a one to three quarters of an inch connection to which a hose can be hooked up and small areas can be hand watered.

METERING

It is important for a golf course to understand the amount of water it is consuming. Meters should be placed at wells and pump stations, and monitored. A designated person should be in charge of taking daily readings. Using a central computer can also be helpful in comparing the projected flow to the actual output of the pump station. It is an easy way to see if the programming in the computer is correctly calibrated with proper nozzles, head types, and valving.

PRESSURE REGULATING VALVES

On properties with significant elevation variability it may be necessary to install various pressure regulating valves to control or maintain pressures throughout the system. These critical devices should be actively managed with weekly observations, quarterly inspections, and annual cleaning/rebuilding. Maintaining proper pressures reduces system fatigue, breakage, pressure losses, and water hammer.